Metal Fabrication Experts

With over three decades of experience in metal fabrication, our mission is to deliver top-tier sheet metal and heavy fabrication solutions tailored to your business needs.

Our broad industry experience ensures we precisely address your unique requirements, focusing on boosting project efficiency, quality, and cost-effectiveness.

We excel in providing high-quality Hardox® Wearparts and offer exceptional design, engineering, and fabrication services to ensure your project’s success.

Our Fabrication Solutions

From Precision Sheet Metal to Durable Wear Parts and Heavy Fabrication

Heavy Fabrication

From complex assemblies to large-scale weldments, we deliver high-quality, heavy-duty solutions that support the critical operations of various industries.

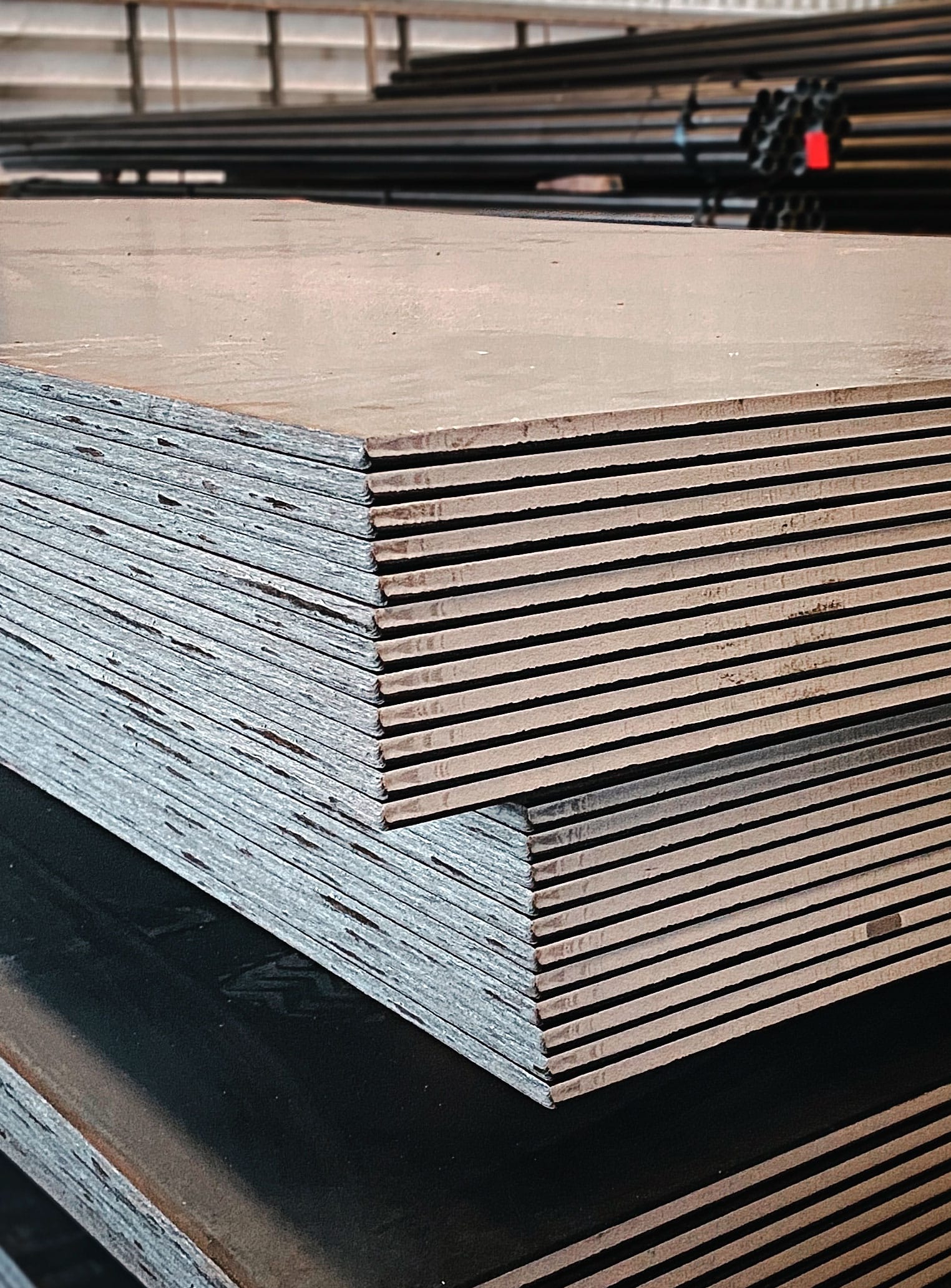

Sheet Metal Fabrication

We craft sheet metal parts like enclosures and frames, ensuring high tolerance, quality, and impeccable cosmetic appearance to meet your project’s requirements.

Schaffer Wear Parts

We provide aftermarket wear solutions that extend equipment lifespan, minimizing downtime and cutting operational costs to boost efficiency and performance.

Engineering Precision Across Critical Infrastructure Industries

Our metal fabrication expertise spans a variety of industries, including construction, mining, rail, energy, oil, and gas. We understand and address each sector’s unique challenges.

Our knowledgeable team deeply focuses on the unique needs of your product, employing innovation combined with industry best practices to ensure the best possible outcomes for quality, lead time, and cost efficiency.

Mining

Our experience in mining and aggregate replacement wear parts translates into rapid turnaround times.

Agriculture

Wear solutions, heavy fabrication, and precision sheet metal fabrication for agriculture OEMs, optimizing equipment lifespan.

Heavy Equipment

Ensure top-quality equipment is tailored to diverse heavy applications, including precision fabrication, rugged duty implements, and part replacements.

Rail

Extensive expertise in crafting high-tolerance wear parts components for rail cars and train systems.

Engineering Precision Across Critical Infrastructure Industries

Our metal fabrication expertise spans a variety of industries, including construction, mining, rail, energy, oil, and gas. We understand and address each sector’s unique challenges.

Our knowledgeable team deeply focuses on the unique needs of your product, employing innovation combined with industry best practices to ensure the best possible outcomes for quality, lead time, and cost efficiency.

Mining

Our experience in mining and aggregate replacement wear parts translates into rapid turnaround times.

Heavy Equipment

Ensure top-quality equipment is tailored to diverse heavy applications, including precision fabrication, rugged duty implements, and part replacements.

Agriculture

Wear solutions, heavy fabrication, and precision sheet metal fabrication for agriculture OEMs, optimizing equipment lifespan.

Rail

Extensive expertise in crafting high-tolerance wear parts components for rail cars and train systems.

Our Capabilities

Our Expertise from

Design to Delivery

Our approach integrates cross-functional production and quality planning, manufacturing, assembly, and inventory management, offering a seamless transition from concept to completion.

Design and Engineering

During the pre-production process design, critical features will drive functionality and performance, justifying manufacturing costs. We prioritize critical elements to optimize fabrication strategies and avoid quality risks.

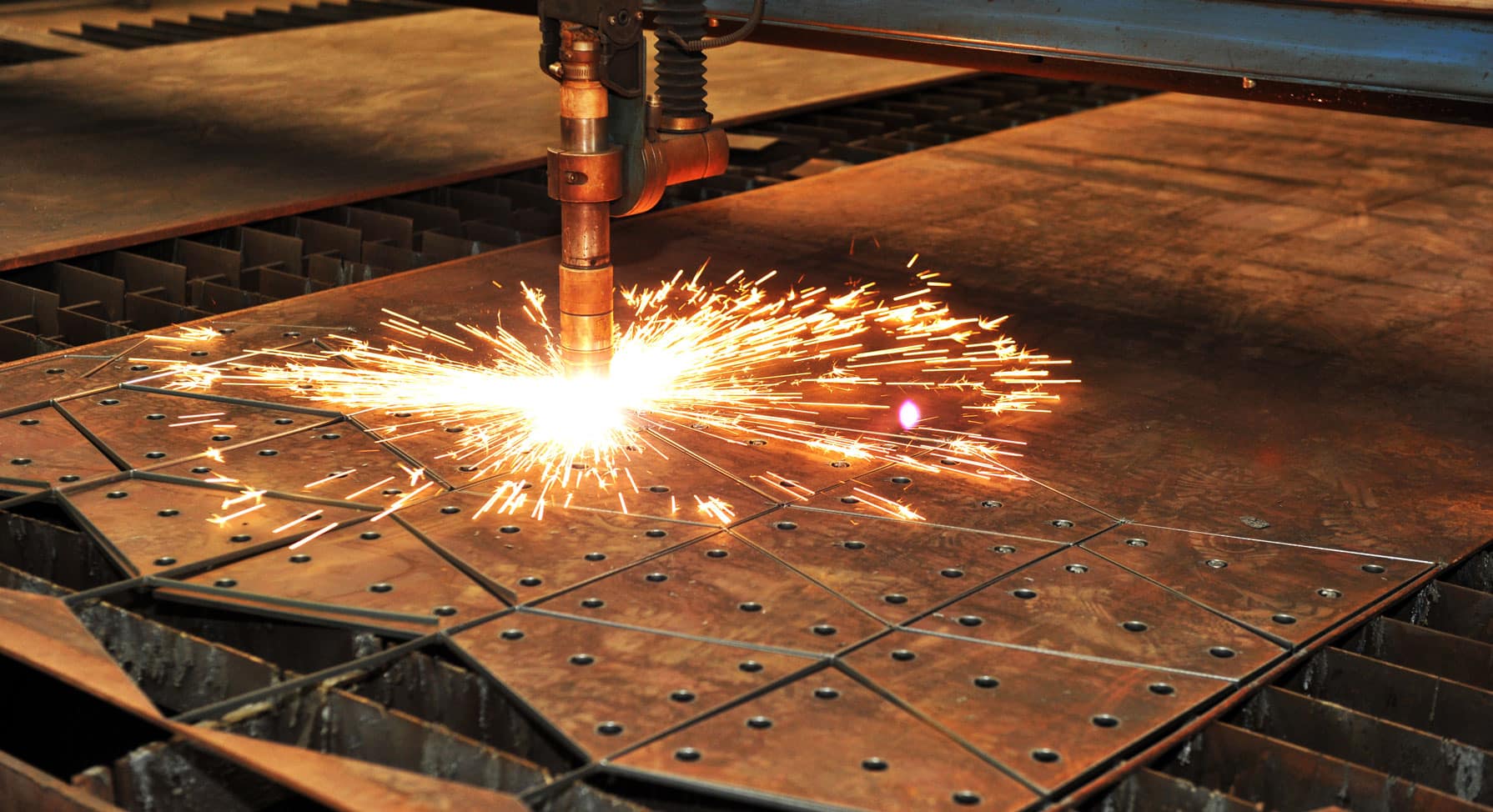

Manufacturing

Fabrication must be a trusted partner in strategy, innovation, and creativity. It’s more than just cutting and welding—it’s about envisioning possibilities, optimizing processes, and delivering precision-focused solutions that drive success.

Strategic Inventory Management

Minimizes downtime and delays, enhancing manufacturing efficiency and meeting delivery timelines. Supplier-led initiatives guarantee timely access to parts, improving workflow continuity and supporting operational goals effectively.

Where Metal Meets Mission

Tons of steel processed annually

Sq Ft. Facility

Team Members

Years of experience in large format metal fabrication

Precision, expertise, and innovation—delivering high-quality metal fabrication solutions with excellence and efficiency.

With a commitment to excellence, we lead the metal fabrication industry, delivering high-quality solutions. Our capabilities, skilled workforce, and technology enable us to handle complex projects with precision. Decades of experience and continuous improvement ensure every component meets the highest standards.

CONTACT US TODAY

Leverage our expertise for your project success.

Partner with us and benefit from our extensive toolkit, industry-specific experience, and reliable processes and systems you can trust to convert metal fabrication requirements into product manufacturing wins.

Phone: (715) 825-2424

Address: 109 Industrial Ave, Milltown, WI 54858

- Monday - Friday 6AM–4:30PM

- Saturday - Sunday Closed

CONTACT US TODAY

Leverage our expertise for your project success.

Partner with us and benefit from our extensive toolkit, industry-specific experience, and reliable processes and systems you can trust to convert metal fabrication requirements into product manufacturing wins.